Photocell Advance™

Integrated Lux Detection — Smarter Daylight Control

Seamless, accurate daylight sensing — without visible photocells.

Maintain a clean luminaire design while unlocking automatic dusk-to-dawn operation, daylight harvesting, and energy savings.

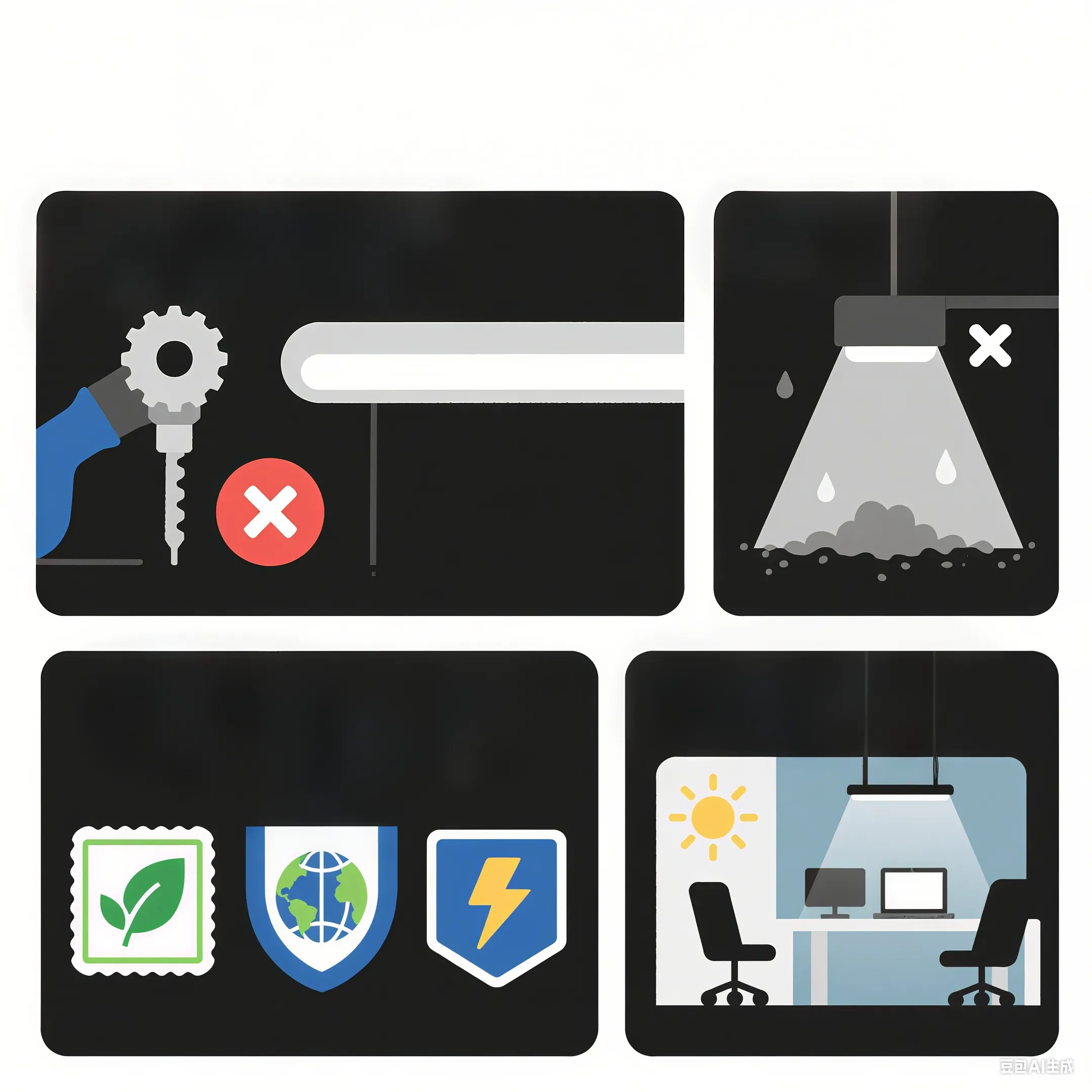

The Challenge with Traditional Daylight Sensors

In typical lighting designs, external photocells are used to detect ambient light. These sensors often require drilling holes through the luminaire housing or mounting on exposed surfaces. This:

- Increases manufacturing steps & complexity

- Breaks the clean design of architectural luminaires

- Creates exposure points for dirt, moisture, and UV damage

The True Cost of External Photocells

🚨 Up to 22% failure rate in outdoor projects

Dirty, UV-damaged or moisture-affected sensors → complaints, warranty costs, and unplanned technician call-outs.

🚨 +12–15% more production time per luminaire

Drilling, sealing, extra assembly and testing → lower productivity, higher labour costs, and delayed shipments.

🚨 Premium tenders lost over a visible sensor

Architects and planners reject luminaires that break the design line → lost sales on high-value projects.

More failures. More costs. More lost projects.

4 Key Functions:

🔍 Accurate Lux Measurement

Sensors operate fully enclosed, eliminating the need for any external exposure. This simplifies production and preserves clean fixture design.

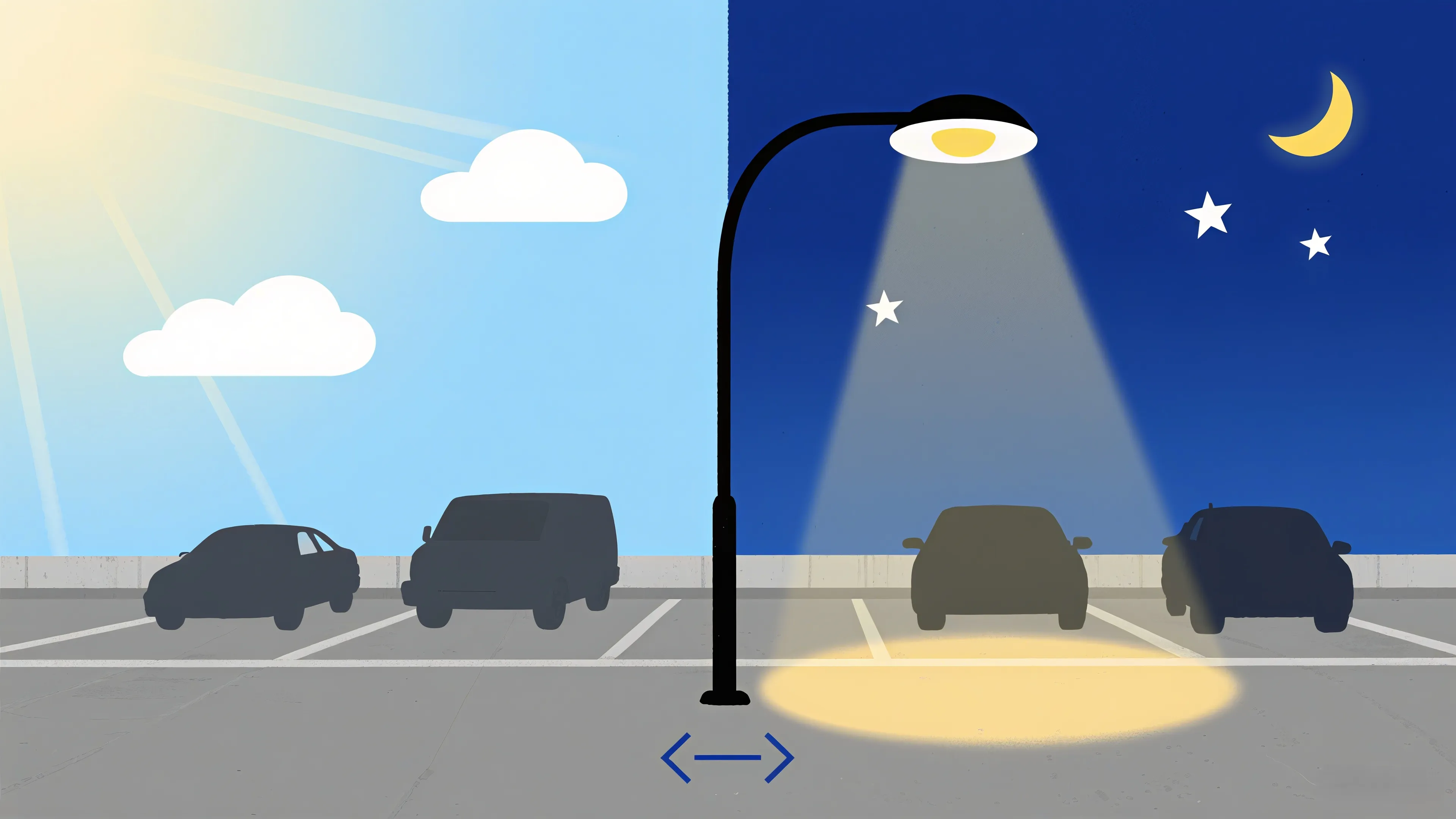

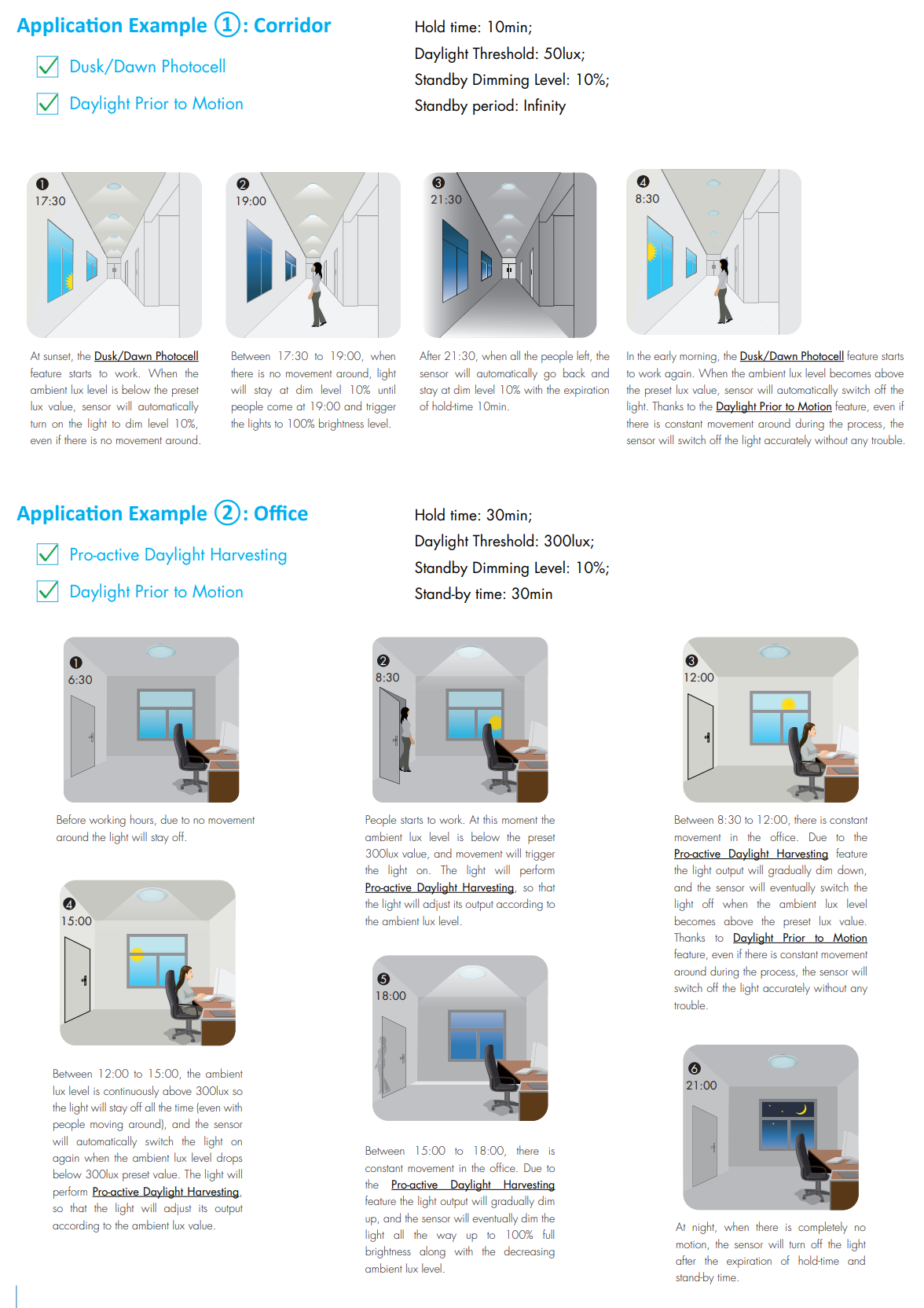

🌅 Dusk & Dawn Auto Control

Lighting automatically turns on at dusk and off at dawn, regardless of motion. Perfect for car parks, pathways, public areas, and façade lighting.

🚦Daylight Priority Switching

When sufficient natural light is detected, the system keeps lights off — even if motion is present. This reduces energy consumption in bright environments.

🌞 Proactive Daylight Harvesting

Continuously adjusts artificial lighting based on real-time daylight levels, maximizing energy savings while maintaining consistent visual comfort.

Feature |

Photocell Advance™ |

Traditional Photocell |

|---|---|---|

External opening required |

❌ No |

✅ Yes |

Aesthetic impact |

None |

Visible sensor |

Risk of dirt/UV damage |

Low |

High |

Calibration accuracy |

High & stable |

Variable |

Why It Matters to OEMs and Project Designers?

1. No need for drilling or external photocell integration - reduces production steps and material complexity

2. Maintains design integrity — ideal for architectural, linear, and minimalist lighting

3. Improves reliability — no exposed components prone to dirt, damage, or UV degradation

4. Supports global green building standards — LEED, BREEAM, and energy codes

5. Enhances occupant comfort — automated lighting for changing daylight

Where It Shines (Ideal Applications)

🏛️ Architectural Lighting – Minimalist lines, no visible sensors

🌳 Outdoor Fixtures – Weatherproof reliability without exposed parts

🏢 Offices & Commercial – Smart daylight harvesting for energy code compliance

Application Examples and Settings

Why OEMs Trust Photocell Advance™

✅ Lab-verified precision: ≥95% lux accuracy, tested under real outdoor stress conditions.

✅ Future-proof compliance: LEED v4 · BREEAM · EN 15193.

✅ Integration advantage: −15% production time per luminaire.

✅ Support that matters: Direct access to Hytronik engineers, 48-hour response time, 5-year warranty.

More than just a feature — it’s a control technology built to protect your time, your design, and your reputation.