RETROFITTING INDUSTRIAL LIGHTING: HOW TO UPGRADE YOUR EXISTING SYSTEMS WITH SMART CONTROL

As energy costs rise and sustainability becomes a global priority, industries across Europe face increasing pressure to improve the efficiency of their existing infrastructure. Lighting, which can account for up to 15% of industrial energy consumption, is a key area where significant savings can be made.

But here’s the challenge: more than 80% of the buildings that will be in use by 2050 have already been built (Source: World Economic Forum). This means retrofitting is essential to keep up with regulations and reduce costs.

In this post, we’ll cover:

Upgrading with Bluetooth Mesh technology

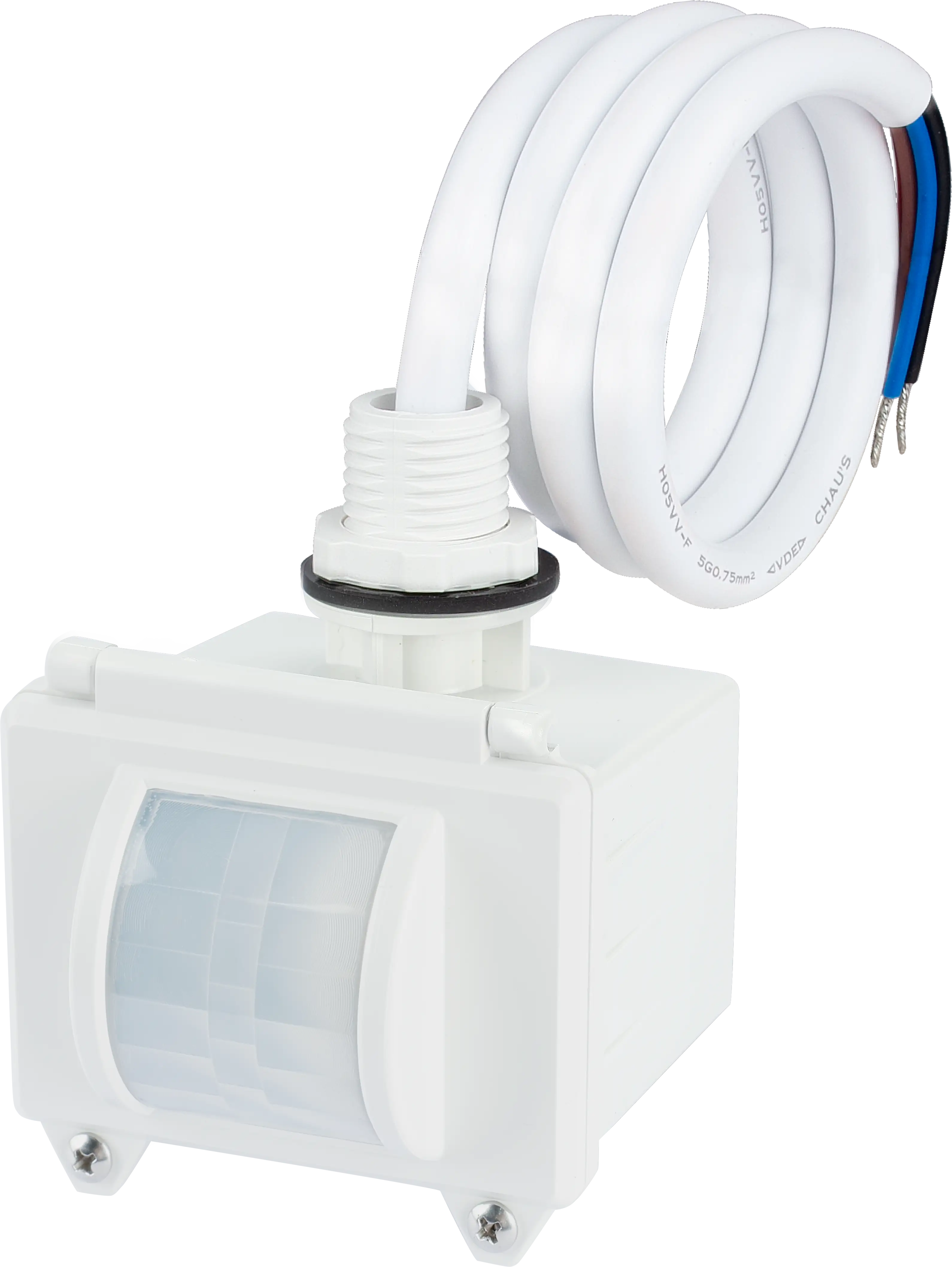

Seamless wireless control to manage lighting systems effectively.Smart sensors for presence detection

Save energy by illuminating only when needed.Daylight harvesting to optimise energy use

Automatically adjust lighting based on natural daylight.Automated emergency lighting control

Ensure safety and compliance without manual intervention.

4 Steps to Retrofit Industrial Lighting with Smart Controls:

Watch this video where our colleague Simon explains these features of our Koolmesh app.